- 1 attendee

- Hosted by Albert Hill

- More

- Liked 0

-

As a direct consequence of the relentless advancement of industrial technology, mass production of goods is now a reality, and the scale of production is growing on a daily basis. As a direct consequence of this, competition among sellers of goods that are functionally equivalent is becoming increasingly cutthroat. At this point in time, we are confronted with the challenge of determining how we can bring down the costs of our products. In order for us to get a handle on this situation, we need to have a solid understanding of the components that go into determining the cost of the item being sold.

It is necessary to reasonably categorize production costs in order to not only make the collection of production costs easier but also to ensure that product costs are calculated accurately. This is because reasonable categorization is necessary in order to ensure that product costs are calculated accurately. The costs of production are segmented into the various economic subcategories that they fall under. Direct materials include things like fuel, power, packaging, and other direct materials in addition to things like raw materials and auxiliary materials. Semi-finished products, spare parts, and outsourcing of semi-finished products are also considered to be direct materials. Other direct expenditures include expenditures that are directly used for product production, whereas direct wages include wages and welfare expenses of employees who are directly engaged in product production. Other direct expenditures include expenditures that are not directly used for product production. In this category, you'll find things like wages for production unit management personnel, employee welfare expenses, production unit fixed asset depreciation fees, rented fixed asset rental fees, repair fees, machine and material consumption, low-value consumables, heating fees, water and electricity fees, office expenses, travel expenses, transportation expenses, insurance fees, design drawing fees, test inspection fees, labor protection fees, season fees, downtime losses d, and season fees.

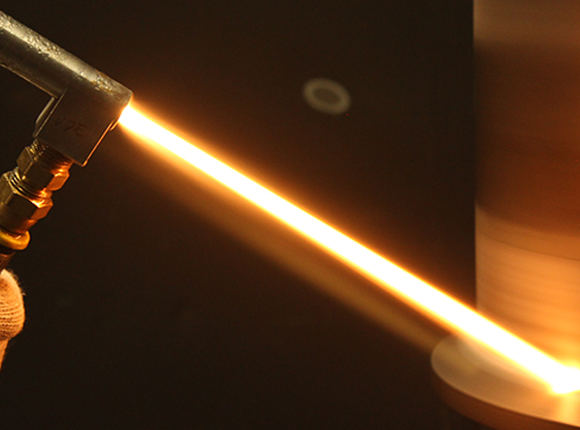

As a direct consequence of the relentless advancement of industrial technology, mass production of goods is now a reality, and the scale of production is growing on a daily basis. As a direct consequence of this, competition among sellers of goods that are functionally equivalent is becoming increasingly cutthroat. At this point in time, we are confronted with the challenge aluminum casting factory of determining how we can bring down the costs of our products. In order for us to get a handle on this situation, we need to have a solid understanding of the components that go into determining the cost of the item being sold.

It is necessary to reasonably categorize production costs in order to not only make the collection of production costs easier but also to ensure that product costs are calculated accurately. This is because reasonable categorization is necessary in order to ensure that product costs are calculated accurately. The costs of production are segmented into the various economic subcategories that they fall under. Direct materials include things like fuel, power, packaging, and other direct materials in addition to things like raw materials and auxiliary materials. Semi-finished products, spare parts, and outsourcing of semi-finished products are also considered to be direct materials. Other direct expenditures include expenditures that are directly used for product production, whereas direct wages include wages and welfare expenses of employees who are directly engaged in product production. Other direct expenditures include expenditures that are not directly used for product production. In this category, you'll find things like wages for production unit management personnel, employee welfare expenses, production unit fixed asset depreciation fees, rented fixed asset rental fees, repair fees, machine and material consumption, low-value consumables, heating fees, water and electricity fees, office expenses, travel expenses, transportation expenses, insurance fees, design drawing fees, test inspection fees, labor protection fees, season fees, downtime losses d, and season fees.

If each of these two hundred products has its own unique design, there is a good chance that many of the materials won't be able to meet the minimum quantity required for economical order. This is one of the primary elements that plays a role in determining the cost. Whether or not the parts share a commonality, as well as whether or not the parts can be used interchangeably, is what will determine whether or not the number of part varieties can be increased while still reducing the amount of money spent on mold costs. If the supply of the materials that are used on the market is unreliable, it may result in the loss of out of stock, which is also a potential loss for the enterprise, but it is still a loss for the enterprise regardless.

During the production cycle of the product, it will be determined whether or not the product is straightforward to produce. The process of product design and development, in addition to the process connection process of the design, production, and sales links, is where the solution to these cost reductions can be found. These processes all work together to create the product.

We are aware, on the basis of the findings of the investigation into the origins of product costs that were presented in the first part of this discussion, that Surface Finish Services the manufacturing stage in addition to the sales stage and the maintenance stage of the product are responsible for determining the costs of the other parts of the product. This includes non-direct employee wages and benefits in the process of product production, other expenses and expenses incurred in the process of production management, as well as expenses arising from the influence of certain factors that cannot be predicted in the design stage. Additionally, this includes expenses resulting from the influence of certain factors that cannot be predicted in the design stage.

During the stage of product design, it is not difficult to discover that certain cost items, such as direct materials, direct wages, and manufacturing expenses, have already been determined. This is because these things have already been die casting products determined prior to the stage of product design. Every stage of the product that is put into production after the design stage of the product has been completed has a close relationship to the design stage of the product. After the design stage of the product has been completed. It is not the calculation of accounting and statistics that can reduce the cost of a product; rather, it is the performance and function of the product that determines the cost of the product. a product's price is determined by how well it performs and functions. The design of a product needs to follow a certain procedure in order to keep costs under control, and product designers are typically the ones who strive for perfection. It is a toss-up between having perfect performance and having a low price.

While having perfect performance is preferable, the product will be removed from the market if the price is ignored. When developing a product, it is not the designer's responsibility to bring their vision to life; rather, it is the designer's responsibility to cater to the requirements of the buyer. If there is any benefit to design, it is to reduce the costs of management and the amount of time it takes to design products. Design also helps reduce the amount of time it takes to design buildings. The fact that these are components that help keep product costs under control is one thing; however, much further than these components lies a connotation that is much richer. If we want to have any chance of finding a solution to this problem, we need to investigate it from the perspective of the entire supply chain. Only then will we have any chance of success. To demonstrate our point, let's take a look at the following illustration:For example, during the most recent quarter, the development of 200 brand-new products took place.

-

Category

Internet -

Date & Time

Jun 27 2023 at 12:00 AM - Oct 27 2023 at 12:15 AM -

Location & full address

San Jose, California -

Event Admins

Albert Hill